Dredging, a critical process in the maritime industry, involves the excavation and removal of sediment, debris, and other materials from waterways. The primary purpose of dredging is to maintain or increase the depth of navigable waterways, to ensure safe passage for large vessels, and enhance port efficiency. Dredging is also critical in support of environmental management and economic growth. The integration of new technologies in operational research and vessel simulation technologies have revolutionized dredging operations with unprecedented efficiency in training and project planning.

In the United States, dredging operations are primarily performed by the United States Army Corps of Engineers, private contractors, and port authorities. Dredging methods vary by project requirements and environmental conditions. Standard techniques include mechanical dredging with clamshell buckets or backhoes, hydraulic dredging with suction pipes, and specialized methods such as water injection dredging.

Advantages of Dredging Operational Research

Operational research in dredging brings multiple advantages to the industry:

- Improved Efficiency

Dredging operational research optimizes resource allocation and project scheduling by reducing project duration and costs, and increasing capacity. - Enhanced Decision-making

Data-driven insights enable project managers to make more informed decisions about project execution and resource allocations. - Risk Mitigation

Predictive models help identify potential risks and develop contingency plans, reducing the likelihood of project delays or cost overruns. - Improved Safety

Dredging operational research contributes to safer working conditions for dredging crews by identifying potential hazards and optimizing operations. - Cost Savings

Dredging operational research can reduce operation costs through improved efficiency and resource utilization.

The Role of Simulation Technology in Dredging Operations

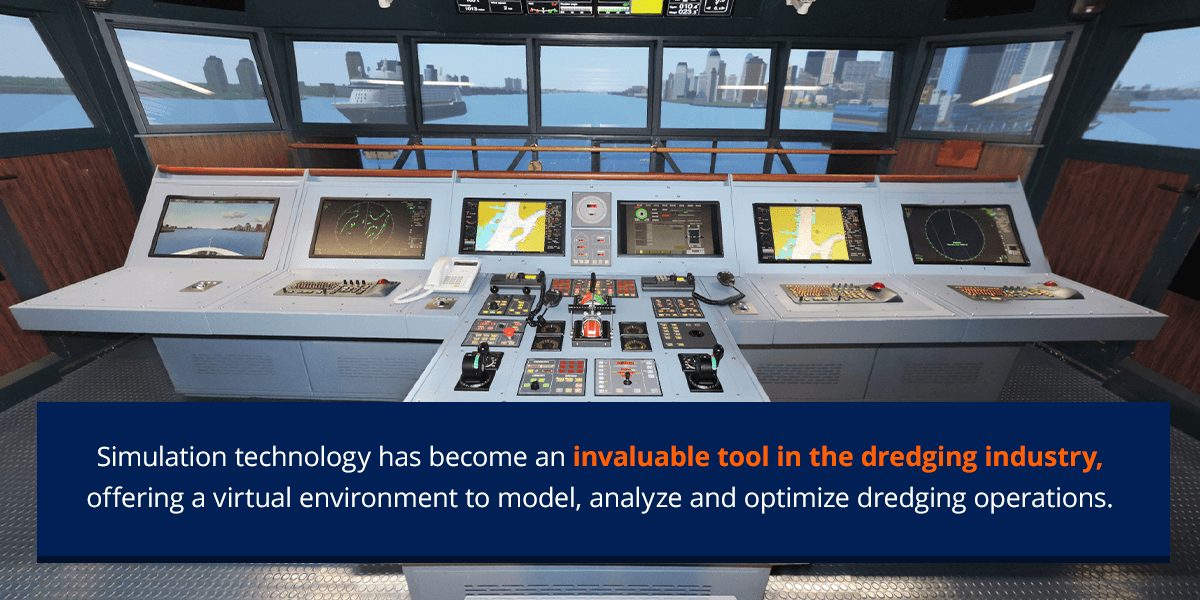

Simulation technology has become an invaluable tool in the dredging industry, offering a virtual environment to model, analyze, and optimize dredging operations. Advanced simulation software can replicate complex dredging scenarios, incorporating factors such as sediment characteristics, hydrodynamic conditions, and equipment specifications.

The advent of high-fidelity simulation in dredging has revolutionized how companies approach training, project planning, and operational optimization. Dredging simulation can leverage advanced computer models and visualization techniques to accurately recreate complex maritime environments.

Dredging simulation software has diverse applications across the industry:

- Training and Education

Dredging simulation software provides an immersive platform for operators to hone their skills without the risks associated with real-world operations. These software solutions offer customizable training modules tailored to specific equipment types, dredging techniques, and operational scenarios. - Planning and Accurate Modeling for Dredge Plans

Simulation software creates accurate models of dredging operations, allowing project managers to visualize project scope, estimate duration and costs, and identify potential challenges. Advanced simulation models can integrate various data sources, including hydrographic surveys, weather forecasts, and equipment specifications, to provide comprehensive and accurate project outcome predictions. - Integrated Systems

Dredging simulation software allows operators to combine surveying and dredging, leveraging real-time data collection and analysis to improve decision-making processes and operational efficiency. High-precision positioning and depth measurement technologies, combined with real-time progress monitoring and visualization, allow for unprecedented accuracy in dredging operations.

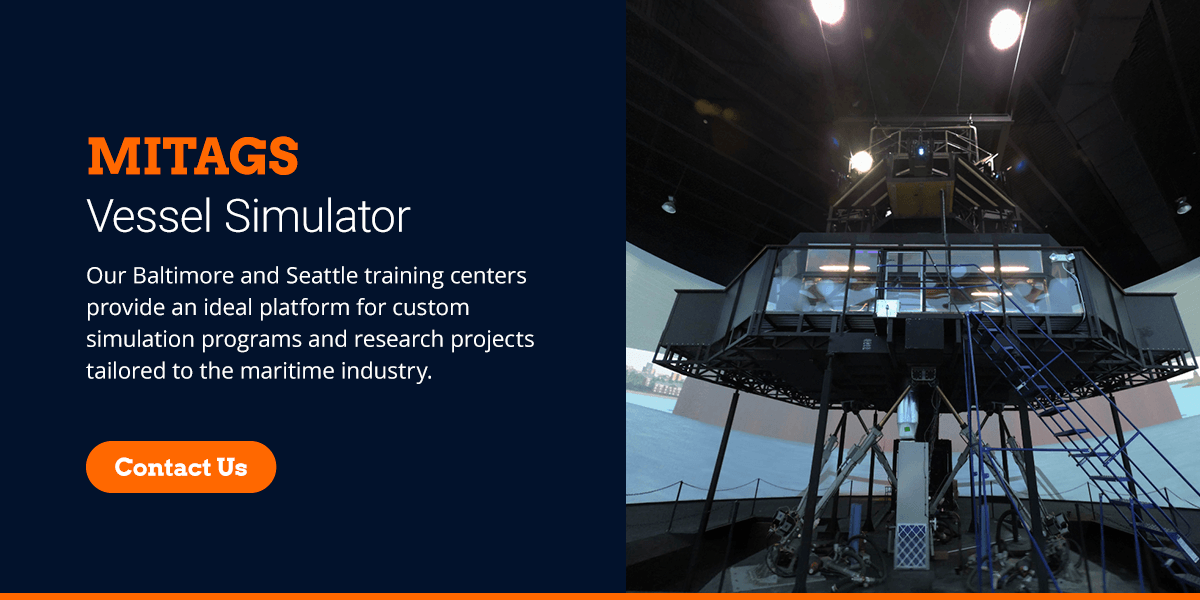

MITAGS Vessel Simulator

With over 50 years as a leader in maritime training, the Maritime Institute of Technology and Graduate Studies (MITAGS) stands at the forefront of operational research and simulation services.

MITAGS’ state-of-the-art full mission bridge simulator offers a comprehensive range of capabilities. Its high-fidelity visual systems provide a 360-degree field of view, that immerses trainees and researchers in thousands of realistic marine environments around the world. The MITAGS simulator also features accurate vessel hydrodynamics and environmental handling, customizable scenarios, integrations with real-world navigation equipment, and advanced data logging and analysis tools for research and training.

These features create an immersive and realistic training environment that effectively prepares operators and mariners for the challenges they may face in real-life scenarios. Our simulator provides a platform for evaluating different approaches before committing resources, refining protocols, and researching innovative technologies and methods.

Our Baltimore and Seattle training centers provide an ideal platform for custom simulation programs and research projects tailored to the maritime industry.